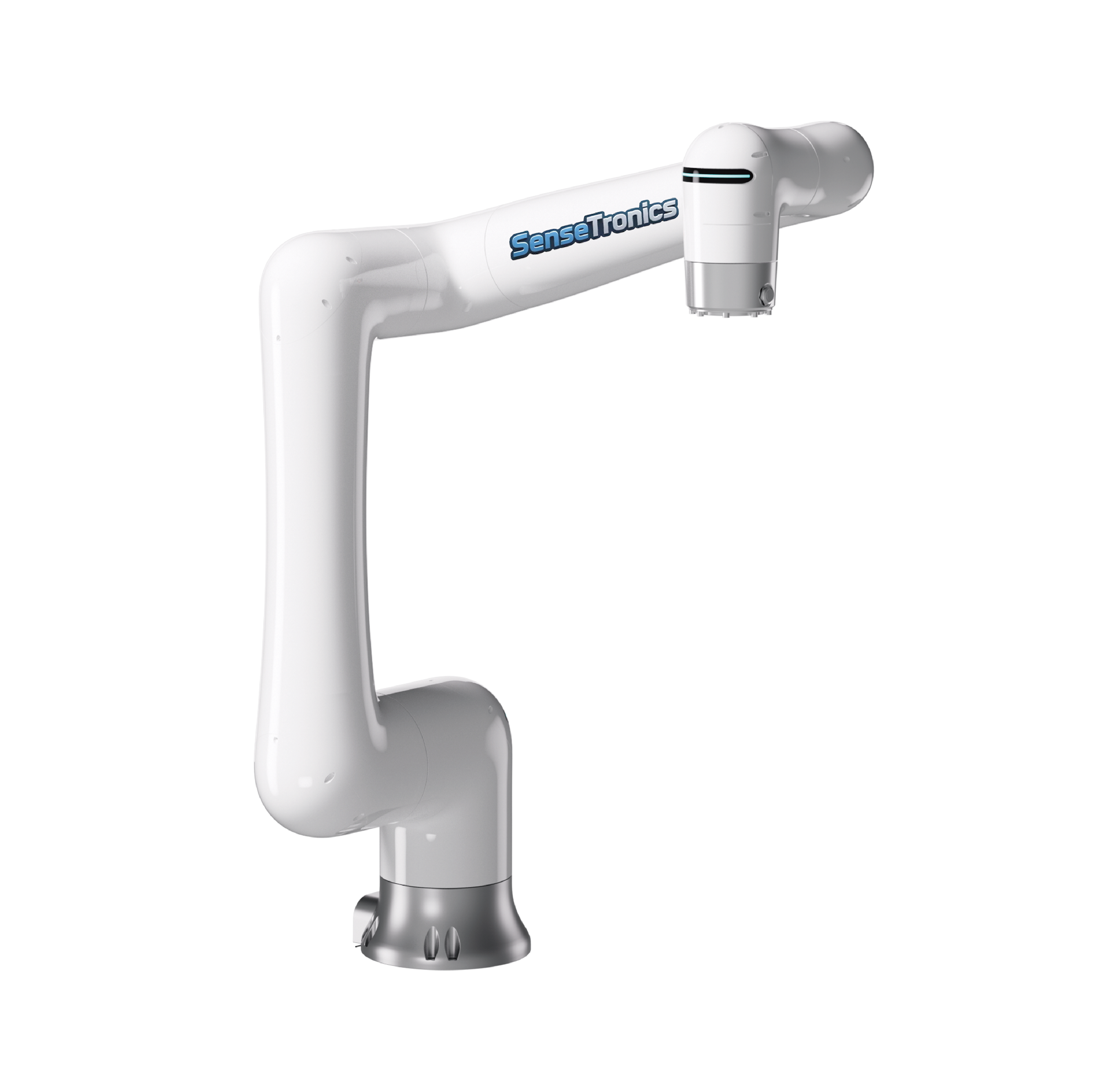

Collaborative Robots

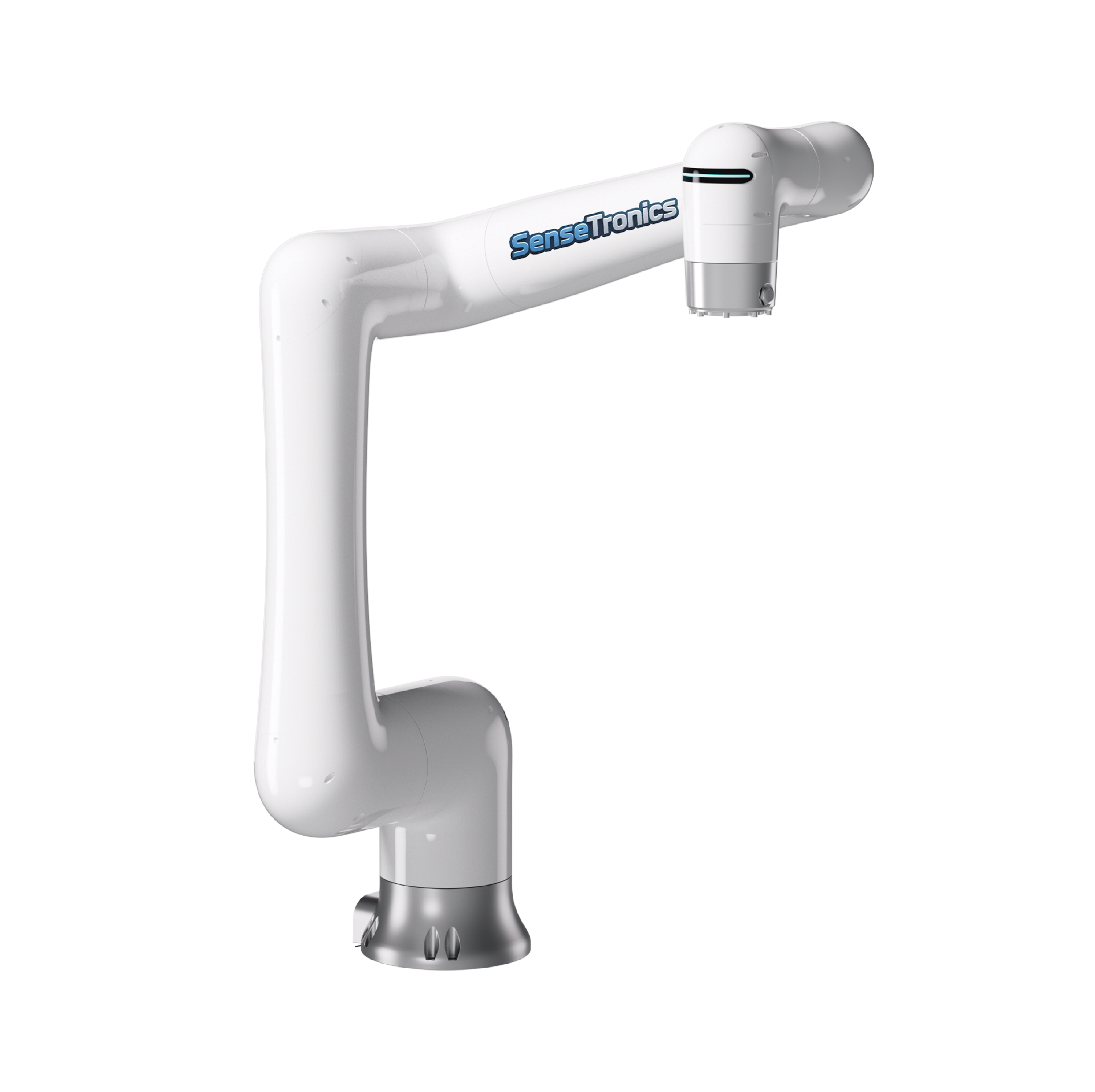

Advanced collaborative robots designed for safe human-robot interaction in various industrial applications.

Safe & Efficient Collaboration

Our collaborative robots are designed to work alongside human operators without safety barriers, enabling seamless integration into existing workflows while maintaining the highest safety standards.

Safety First

Advanced sensors and safety systems ensure safe operation in shared workspaces.

Easy Integration

Plug-and-play setup with intuitive programming interfaces for quick deployment.

Cost Effective

Reduce operational costs while improving productivity and workplace safety.

Flexible Applications

Versatile solutions for assembly, pick-and-place, quality inspection, and more.

Our Collaborative Robots

Choose the perfect cobot for your application

Showing our most popular models • 7 total models available

Applications

Versatile solutions for collaborative automation

Assembly Operations

Precision assembly operations in electronics and automotive industries

Pick & Place

Efficient material handling and sorting applications

Quality Inspection

Automated inspection and quality control processes

Packaging Operations

Automated packaging and labeling operations

Machine Tending

Loading and unloading CNC machines and other equipment

Welding Operations

Collaborative welding with human oversight

Polishing & Finishing

Surface finishing and polishing applications

Testing & Measurement

Automated testing and measurement processes

common.faq

cobots.page.faq.subtitle

Ready to Implement Collaborative Automation?

Discover how our collaborative robots can improve safety, efficiency, and productivity in your workplace.