ST-30PL-PRO Palletizer Robot

ST-30PL-PRO and PRO-G models represent a significant advancement in palletizing technology, offering increased capacity and performance within the PRO series. This robot delivers exceptional performance metrics, setting new industry standards for speed, accuracy, and safety, bolstered by its highly reliable industrial-grade force-sensors. It integrates a sophisticated 10-level collision detection system and advanced sensor safety features, ensuring continuous operational safety even in the event of a single fault. The robot's integrated design is both light and flexible, maintaining a compact footprint that facilitates effortless workstation deployment and rapid configuration for new tasks. The ST-30PL-PRO is highly adaptable and extensively used across diverse sectors such as food processing, pharmaceuticals, 3C manufacturing, daily chemical production, and e-commerce, underscoring its versatility and high-efficiency capabilities.

Technical Specifications

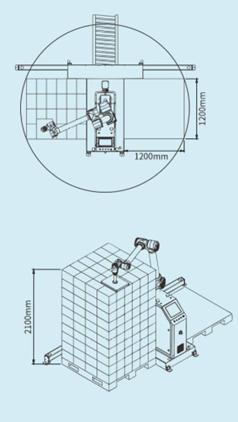

Product Diagram

Detailed technical diagram showing dimensions and specifications

Applications

Versatile solutions for various industrial applications

High-Speed Pick & Place

Advanced high-speed operations for manufacturing and packaging lines with exceptional performance.

Precision Assembly

Accurate assembly operations requiring high repeatability and positioning accuracy for various components.

Packaging Operations

Automated packaging and labeling operations with vision-guided capabilities for quality control.

Sorting Applications

High-speed sorting and classification operations for various products in logistics environments.

Quality Inspection

Automated inspection and quality control processes with integrated vision systems for defect detection.

Material Handling

Efficient handling and transfer of materials in production lines with precise positioning and speed.

Advanced Palletizing Technology for High-Capacity Operations

Experience the significant advancement in palletizing technology with the ST-30PL-PRO for your most demanding automated packaging operations.